| Indian and Oriental Armour By Lord Egerton [ The only account of Indo-Persian damascus barrel making ] It is said that the Persians distinguish by ten different names the varieties of watering. One of the most prized and rare is that which takes its name from the grains of yellow sand. There are, however, four main patterns generally recognised :— 1. " Kirk narduban," meaning the forty steps or rungs of the laduer, in allusion to the transverse markings of fine grey or black watering. The idea is also expressed in an inscription on one of the blades, that the undulations of the steel resemble a net across running water. 2. " Qará khorásán," nearly black, with fine undulations proceeding like water either from the point to the hilt, or the reverse way. 3. Qará Tábán, " brilliant black," with larger watering and more grey in tone. 4. Sham, or simple Damascus, including all other varieties. On the introduction of the use of firearms, the methodss long and perhaps exclusively known to the Asiatics, of manufacturing sword-blades of peculiar excellence, was transferred with' some modification to that of gun-barrels, and are still in use. In Persia, Kabul, the Punjab, and Hind the same general principles prevail, but the matchlocks of the last are held deservedly in the highest estimation. In some parts of India the workmen prefer for the material of their barrels the iron of old sugar boilers, but they use in Kashmir the iron of Bajaur (in the country of the Yusufzai) as it comes from the smelting furnace, after receiving a few blows whilst hot, which condense it into a rude kind of pig, the weight of which varies from five to eight seers (10 to 16 Ibs.), and which sells as high as 4d. a pound. The first process consists in cutting the pig when heated into narrow strips witli a cold chisel, and in this operation the iron loses one-fourth of its gross weight. Each of these strips separately is brought to welding heat, and worked smartly under the hammers of two men on a block of limestone as an anvil. When the slag is expelled, each strip is drawn out by the hammer into a strap about 2 feet long and 11/5 inch broad, and 1/5th inch thick. One of these straps has its ends so brought together as to enable it to include about 20 other short straps cut up for the purpose, some being placed on their edge, and others wedged in between the lengths, во as to form a compact mass. It is then put into the fire and lightly heated, receiving a few blows upon both faces as well as upon the edges. It is next smeared over with a paste of clay and water, and when dried it is exposed first to a light welding heat, and after a slight hammering to a stronger heat, when it is vigorously and quickly beaten into four-sided bars In addition to those, Sir Л. Burnes mentions " Akbaree," in which the pattern ran like a skein of silk the whole length of the Made, and "Beguraee," where it waved like a watered silk. About a foot long, and a finger's thickness. These are again heated, separated, and drawn out into square rods about J-inch broad on each face. These are then twisted from right to left, while the part which is to be twisted is heated to a red heat nearly verging upon white. This process is repeated by heating two or three inches at a time, and then cooling it with cold water, till the whole rod is converted into a fine screw, which is made as even as possible. To make an Iran barrel six or eight rods are required. When eight are employed, four of them have the twist from right to left, and four from left to right. Every rod after having been slightly heated is lightly hammered on its two opposite sides equally, so that two sides have the threads beaten down, and the two others have the threads standing, and retaining their original roundness. Each rod is now made up of lengths of the same direction of twist, and is laid parallel to the other, so that rods of opposite twist are in alternate succession.1 The steel having been formed into bars is now ready for manufacture into gun-barrels. The extremities of the bars are welded together, and the baud or skelp is now ready for being formed into a hollow cylinder through being twisted in a spiral line upon itself, which is begun at the breech or thicker end, and continued to the muzzle. When the twisting is so far completed that the edges of all the twists stand even, and the cylinder is nearly equal, it is coated with a thin paste of clay and water, and is then ready for being welded. A welding heat is first taken in the middle of the cylinder, and the edges of the twists are brought together by the breech being struck down upon the stone anvil perpendicularly for the purpose of jumping up the edges. The welding is constantly repeated, so that the twist, which was jumped up, is successively hammered when the heat is well on, till the barrel has been welded up to the muzzle. This process is then repeated, commencing from the middle to the breech, and afterwards from the middle to the muzzle, during which an iron rod is introduced at each end and tised as a mandril. A third heat nearly red is now taken at the whole surface of the barrel, which is then made regular and level by smartly hammering it. The barrel is then fixed horizontally through a hole in an upright post and bored, after which its surface is filed, polished, and prepared for bringing out the damasked lines. " Jauhar " is brought out through biting the whole surface with " kasis," a sulphate of iron. The barrel is completely freed from grease or oil by being well rubbed with dry ashes and a clean rag. About three drachms of sulphate of iron in powder is mixed with as much water as is sufficient to bring it to the consistence of thick paste which is smeared equally over the whole surface of the barrel, the nmzzle and breech being at the same time carefully plugged. About two hours afterwards, when the metal has assumed a blackish colour, the coating is rubbed oft', and the barrel cleaned as before. 1 Barrels are called " pechdár " when plain or simply twisted, "jnulmrdár " tvheu dunmsked. For the latter the rods are disposed according to the kind of brilliant or damasked lines to be produced, called either from the country as " Iran " or Persian, or from the figure, as " pigeon's eye," " lover's knot," " chain". The barrel is then smeared with a preparation composed of the same quantity of sulphate of iron and four ounces of water, and is hung up in the well. Every gunsmith has, in the floor of his shop, a well about two yards deep, the bottom of which is covered with a layer of fresh horse-dung half a yard thick. Suspended by a string from the cross stick at the mouth of the well, the barrel which has been covered with the mixture as before is taken out every morning and cleaned with dry ashes and cloth, and hung up for 24 hours with a coating of the solution. This process is continued for 20 days or a month till prominent lines are formed on the surface of the barrel, separated from each other more or less by other depressed lines or grooves ; the former will be found to have the same direction as that of the thread of the screw in the twisted rods. The prominent lines when rubbed are bright and of a colour somewhat approaching silver, while the depressed lines are dark and form the pattern. The " zanjir " or chain damask consists in the introduction of a band of prominent and brilliant lines disposed like the links of a chain between parallel plain lines of damask. The processes are the same as before described in cutting up the " pig," and in reducing the strips into straps, but the " pie " or " ghilaf " contains only eight lengths, which when welded is drawn out into straps 1/2 inch broad and 1/8 inch thick. One of these straps being heated is bent backwards and forwards upon itself in eight continued loops, each an inch long, and is then worked up into straps 1/3 inch broad, and 1/16 inch thick. Three of this kind of strap are required in this pattern, one for the chain and two for the lines. The face of the iron anvil has a perpendicular hollow about one-quarter of an inch deep, and about one-third of an inch across. One end of the strap is laid while cold across this groove, and driven down into it by a small chisel and hammer, by which the strap receives a bend or angle. Its opposite face is then placed across the die near the acute elbow made by the chisel, and is in like manner wedged into it, after which the operation is reversed until the whole band is converted into a frill of loops. This frill is then heated, and the operator holding one end with a small pair of tongs brings two pairs of loops together leaving the ends open. This is continued till the frill is much reduced in length through the loops of the strap standing at right angles to its general direction. Different lengths of frill are welded together, so as to form a ribbon six spans long, placed in contact with two plain straps set on edge, and four rods, two on each side twisting alternately, from left to right, and the reverse. The general band of these seven straps is then treated as that for the " Iranian " damask. The chain damask is in general preferred to all other varieties, excepting the silver twist. The Kashmiris still make blades for daggers in the same way, as one which was made for the author at Srinagar to fit an Indian jade handle is damasked, and Moorcroft relates that they made sword blades for him to order, though they did not usually manufacture them. It is said that " jauhar " is imitated in Hindostán by lines being traced in a coating of wax laid over the metal, and the barrel being exposed to the action of sulphate of iron. |

| Research and Information |

| © Damascus-Barrels.com All rights reserved. |

| The Gun and It's Development By W.W. Greener 1909 [ England ] The true English Damascus barrel is prepared from three rods, twisted as described and put together as shown in the twisted riband, and is known technically as three-iron Damascus ; the silver-steel Damascus is similarly made, but of different metal piled in a different order. The rods having been twisted, and the required number welded together, they are sent to the iron-mill and rolled at a red heat into ribands, which have both edges bevelled the same way. There are usually two ribands required for each barrel, one riband or strip to form the breech-end, and another, slightly thinner, to form the fore, or mu/zle, part of the barrel.Silver-steel Damascus Barrel. Upon receiving the ribands of twisted iron, the welder first proceeds to twist them into a spiral form. This is done upon a machine of simple construction, consisting simply of two iron bars, one fixed and the other loose ; in the latter there is a notch or slot to receive one end of the riband. When inserted, the bar is turned round by a winch-handle. The fixed bar prevents the riband from going round, so that it is bent and twisted over the movable rod like the pieces of leather round a whip-stock. The loose bar is removed, the spiral taken from it, and the same process repeated with another riband. The ribands are usually twisted cold, but the breech-ends, if heavy, have to be brought to a red heat before it is possible to twist them, no cogs being used. When very heavy barrels are required, three ribands are used—one for the breech-end, one for the centre, and one for the muzzle-piece. The ends of the ribands, after being twisted into spirals, are drawn out taper and coiled round with the spiral until the extremity is lost, as shown in the representation of a coiled breech-piece of Damascus iron. The coiled riband is next heated, a steel mandrel inserted in the muzzle end, and the coil is welded by hammering. Three men are required—one to hold and turn the coil upon the grooved anvil, and two to strike. The foreman, or the one who holds the coil, has also a small hammer with which he strikes the coil, to show the others in which place to strike. When taken from the fire the coil is first beaten upon an iron plate fixed in the floor, and the end opened upon a swage, or the pene of the anvil, to admit of the mandrel being inserted. When the muzzle or fore-coil has been heated, jumped up, and hammered until thoroughly welded, the breech-end or coil, usually about six inches long, is joined to it. The breech-coil is first welded in the same manner, and a piece is cut out of each coil; the two ribands are welded together and the two coils are joined into one, and form a barrel. The two coils being joined, and all the welds made perfect, the barrels are heated, and the surplus metal removed with a float; the barrels are then hammered until they are black or nearly cold, which finishes the process. This hammering greatly increases the density and tenacity of the metal, and the wear of the barrel depends in a great measure upon its being properly performed. When the barrels are for breech-loaders, the flats are formed on the undersides of the breech-ends. If an octagon barrel is required, it is forged in this form upon Portion of Gun-barrel Coil. a properly shaped anvil; in rifles the barrels are welded from thicker ribands and welded upon smaller mandrels. Another method of making twist barrels is practised in Birmingham, and may be shortly described. The iron is twisted in much the same way as that already described, but steam power is used to turn the winch instead of hand-power. The forge-fires are blown by a steam-fan, instead of the old-fashioned bellows, and the welding is done by one man instead of three. This is accompanied by having a tilt-hammer close to the forge regulated to give sharp, quick, short blows, and capable of being thrown in and out of gear with the foot. The welder is also provided with an anvil, swages, mandrels, etc. When he removes the coil from the fire, he has only to knock in a mandrel, straighten the coil on the anvil, jump it close by striking it on the floor in the usual manner, and place it under the tilt, reheating the coil, and repeating the process until the barrel is properly finished. The appearance of barrels so welded is not so good as that of those hammered by hand, but they are strong and sound, and, on account of less care and labour being bestowed on their production, they are cheaper than hand-forged barrels. The latest method of making the plainer twist barrels is to treat the iron for twisting, and the coils, in a furnace instead of a breeze fire. The theory is that the metal is less liable to be burned, the heat being uniform, and freedom from greys and faulty welds thereby insured. Experience does not fully bear out the theory. Possibly more can yet be done in this line towards producing a perfectly welded and clear barrel. FOREIGN TWIST HARRELS. Damascus iron barrels are forged in Belgium and at other gun-making centres of the Continent by the same methods as practised in England. The chief difference between English and foreign welded barrels exists in the quality of the materials; iron of local manufacture being that generally employed. Another difference is that barrels of a smaller figure and barrels of fancy figures, already alluded to in the paragraph on iron-making, are frequently produced by French, Belgian, and German welders. Softness is the characteristic of Belgian iron ; it is found in all their iron manufactures, and is particularly noticeable and objectionable in their barrels. The welders prefer the soft metal, as being easier to manipulate, welding more freely, and containing fewer surface flaws than hard metal into the composition of which steel largely enters. There is, comparatively, little steel in the Belgian barrel; there are even barrels in which there is no steel, two different qualities of iron serving to produce that distinction which is necessary to produce figure in the finished barrel. The barrel-welders of Belgium are chiefly located at or near Liege. The very best barrel-makers who manufacture for the London, Berlin, and Vienna markets are to be found at Chaudfontaine or Nessonvaux, both places a few miles from Liege. Their method of welding is much the same as that practised by the best English welders, but they work at a smaller forge, and, instead of breeze, use a mixture of coal-dust and clay. The fires being much smaller, the barrels are heated only a few inches at a time, so that greater labour has to be bestowed upon their manufacture. The greatest care is taken to keep the anvils and tools perfectly clean and free from scale, so that no foreign matter can get between the coils and thus affect the soundness of the welds. The type of barrel, which is peculiarly their own, is the fine figured or six-stripe Damascus; in this the figure is very minute, as shown in the illustration, and is produced in the following manner:—-The welders take thirty-two alternate bars of iron and steel, and have them rolled into a sheet T\th of an inch in thickness;the sheet is then split by a machine into square rods. These rods are then twisted after the method of the English welders already described, but to such an extent that the rods resemble the threads of a fine screw, there being as many as eighteen complete turns to the inch. Six of these rods are then welded to each other side by side and rolled into a riband, and the result is a figure so fine Fine Stripe Belgian Damascus Barrel. that it appears no larger than the eye of a needle, and requires special care in browning to obtain markings which can be distinguished. For these fine barrels and for some others the old plan of welding on a chemise is still in use. The other old plan of plating or welding a thin coating of Damascus iron upon a barrel of plain iron has been abandoned, save for very heavy barrels for Two-Iron or " Boston" Damascus Barrel. duck-guns, etc., which are still not infrequently welded of the cheaper scelp, or plain twist iron, then coated with fine figured iron. The regular Belgian barrel of commerce is the double-iron Damascus, " two-iron," or " Boston "—the same barrel by whichever designation known. It differs from the English two-iron Damascus in showing fewer white or light-coloured streaks, and being usually of coarser figure, obtained by piling larger rods in the faggot and again not rolling them to so small a section as is the practice of the English masters. At St Etienne in France, where a manufactory for sporting fire-arms was founded early in the fifteenth century, the Belgian models are followed and the iron of the district is soft and ductile. One plan much used in this district, but by no means original, is the forming of barrels of two twisted rods to one untwisted ; the appearance is that of a " barber's pole," a distinct broad stripe of straight-grained metal running spirally round the barrel from end to end between a broader band of curled Damascus figuring. The only centres at which Damascus barrels are made are, in addition to those already cited, Brescia in northern Italy, and Suhl in Prussia. |

| Manufacture of Damascus Gun Barrel By E. Heuse-Lemoine, 1894 [ Belgium ] "Our barrel industry only reached this enormous productions and gained such an extent on account of its excessive cheapness which results partly from the low rate of wages paid even to the most skilful workmen; and partly from the advantageous geographical situation of this part of our country which in a small area combines all indispensable elements to this industry. Indeed the river 'La Vesdre' and all its affluents are driving a great number of hydraulical wheels which economical motive power is used for boring, polishing, turning and grinding the barrels. The coal pits of the Highland of Herve are situated close at hand which furnish the necessary fuel to the Damascus works; and it is worthy to be noted that these mines furnish a special kind of coal, scarcely to be found anywhere else and is very suitable for our barrel-smiths who we dare say are very skillful to their art, having never done anything else in their life. It is not to be that these men must become first rate Masters in the art of forging, if we consider that the average number of heatings to soldering heat, a barrel receives at least 150 for the fine Damascus tube being 300 heatings for a double barrelled and that if one of these heatings has not well succeeded, that is to say that the barrel has not received its rigourous precise temperature, the tube may be spoiled, either by the alteration of the Damascus, or by the traces of even the smallest want of soldering; you can easily imagine the skill which these workmen possess." From the remotest times, this industry of gun barrel manufacturing has been practiced in the Valley of the Vesdre from Nessonvaux to Chaudfontaine. Under the First French Empire, our renowned barrel-smiths furnished the contingent of the workpeople for the Imperial manufactories. At that time all the barrels for Military guns were forged by hand; the preparing of the iron for these barrels was exclusively performed with charcoal and the superiority of this iron to that prepared with cokes is well known, In our days for the speciality of firearms as we shall show a little further. Now let us come to our subject; THE DAMASCUS BARREL with constitutes not only the chief, the essential part of the firearm, may be said to have become a masterpiece, for it has maintained its place during the incessant progess accomplished in a few years, in firearms. We say in a few years, for indeed, half a century ago the Damascus manufacturing was only in its childhood and it was only when the fulminate was used instead of flintstone that we may say Damascus barrel manufacturing really began. At that time, it is true, one could find here and there in some aristocratial hands a fowling piece with Damascus barrel, but that was a Damascus, the composition of which was very elementary, compared with our present Damascus. Our forgers and workshops then were almost exclusively occupied in making iron barrels and there were but few barrel makers who manufactured tubes or barrels called TWIST BARRELS (in French; Conons Tordus, Tors Ou Torches). This process consisted of making a contortion at each soldering heat which the longitudinal soldering of the iron barrel underwent, which eventually stretched the fibres of the iron into a transversal direction, the process of which was to give more consistency to the tube for resisting or withstanding the dilatation produced by shooting. This work which was very slow gave only an imperfect result with respect to Damas Keening, but it produced the idea that for obtaining a great power of resistance united with the necessary lightness of the sporting gun, the transversal soldering must be highly preferable to the longitudinal, so that, by manual work ribbons were laminated and wound like a spiral as it is practiced in our days. The barrels thus manufactured with good charcoal iron prooved to be already a great progress with respect to solidity, but offered of the Damascus appearance which was visible by certain traces of the spiral produced by the appearance of the fibres or the varnish of the metal. At this time, Paris, that city of luxury, had also its barrel manufacturers such as Bernard, Leclerk etc.who, though small in number, were not less excellent in their art, and it was from Paris that the first imitation came to us for the researches in the combining some mixture of iron and steel in order to produce figures which we call Damascus, such as Turkish Damascus, Bernard, Leclerk and Parisien Damascus etc. to an infinate number of names, as the combinations that compose the figures of the Damascus vary constantly; almost like the designs on our hanging papers in our rooms, with the only difference, that in these the variery is produced by the colours on the surface, whilst the figures on the damascus are produced by the substance or material like the designs or patterns in our linen weavers. What is the Turkish or Curled Damascus, the Horse-shoe nail, the Boston, etc. that are derived from them." ... |

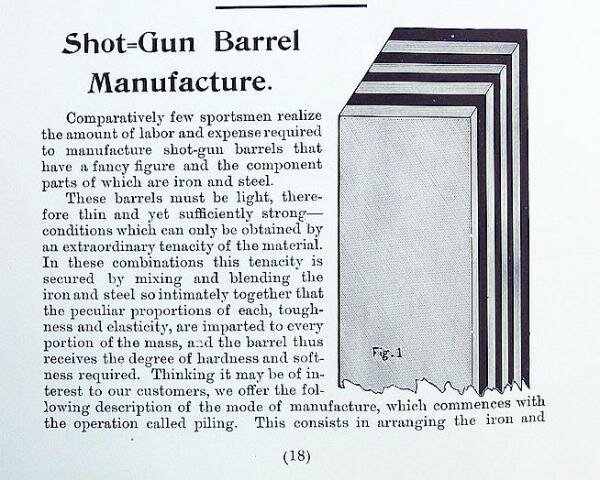

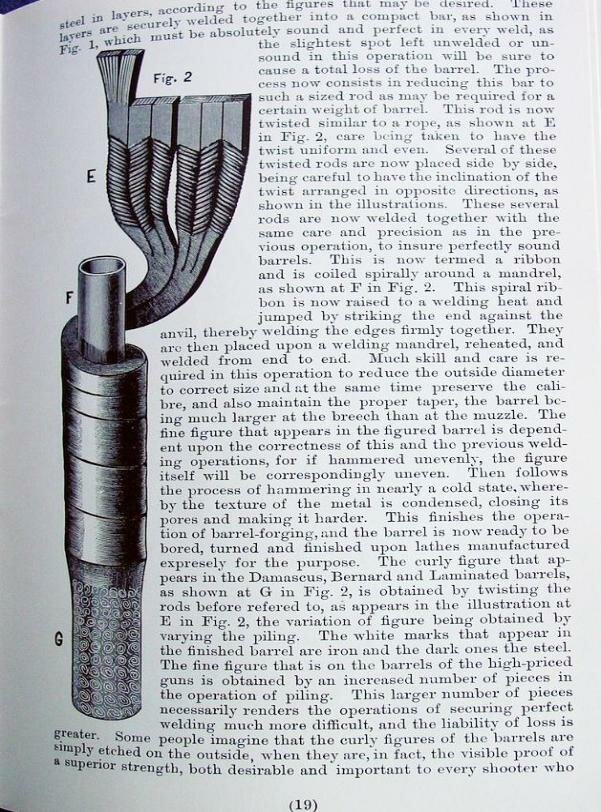

| 1899 Parker Catalog [ America ] |

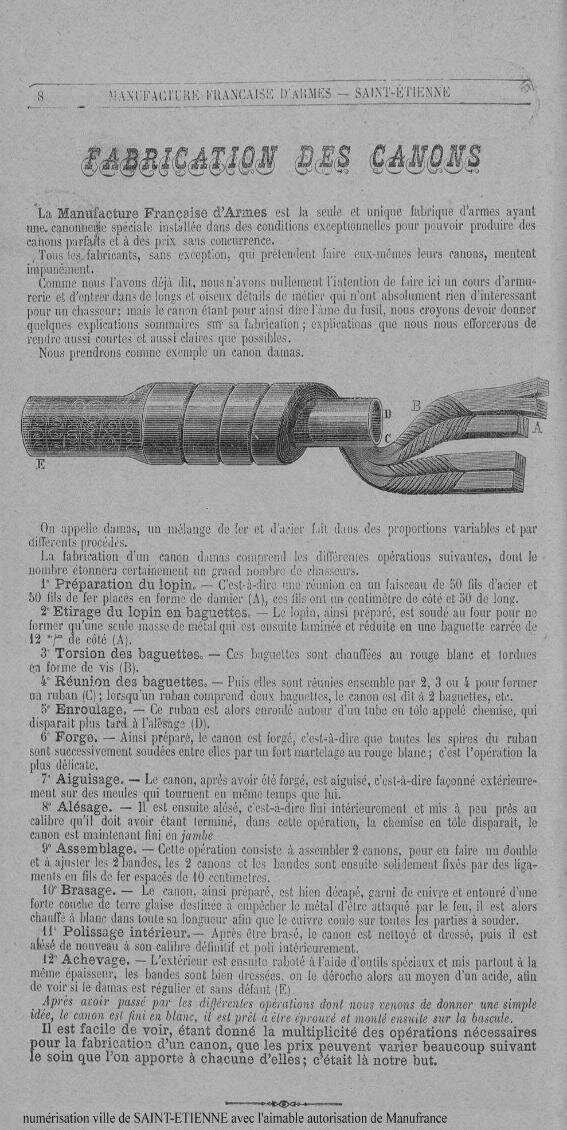

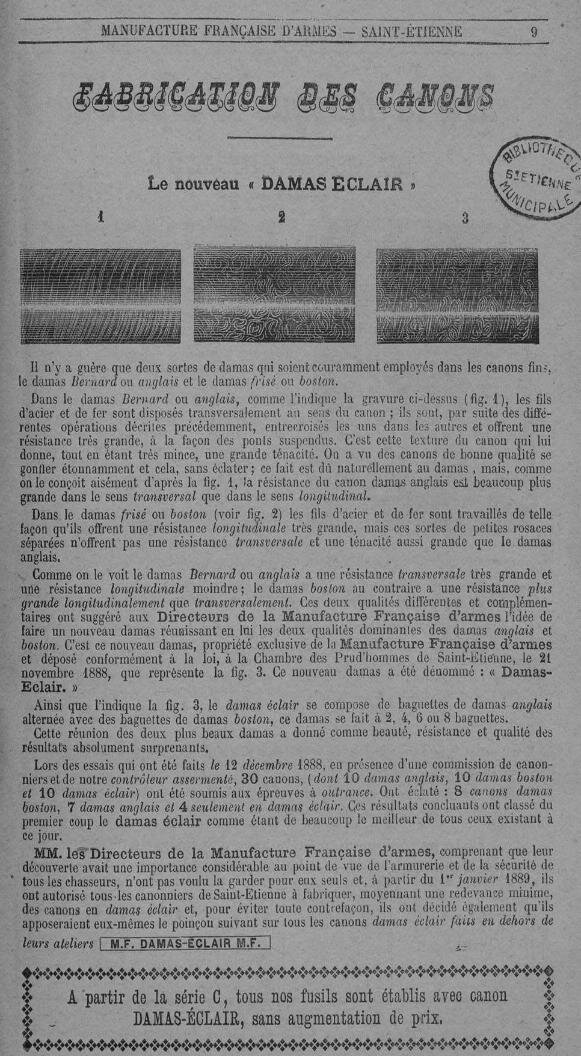

| 1890 Manufrance Catalog [ France ] |

| [ Italy ] |